Our solder bar is made from high purity metal. By means of strict quality control and vacuum deoxidization treatment, the oxide and metallic and nonmetallic impurities are effective minimize. The solder bar is with uniform and glazed surface, good wetting and spreading ability after molten, bright joint and minimum oxide residue after soldering. Our product is suitable for wave and handwork soldering with high quality requirement. To satisfy different soldering and processing require-ments, we provide various kinds of solder bar and thus help our customers to keep up with the rapid development in the electronic industry.

• Oxidation Solder Bar;

• Silver Based Solder Bar;

• Low Melting Temperature Solder Bar;

• High Melting Temperature Solder Bar;

• Other solder bar for articular purposes.

We have researched and produced new varieties of low-melting-point, fast-melt alloy materials-one is Bar-type, another Wire-type which are widely used in fields such as alarm security devices, lighting-proof protective appliances, air-conditioner security warning device, temperature display materials and filled composites during mechanical processing.

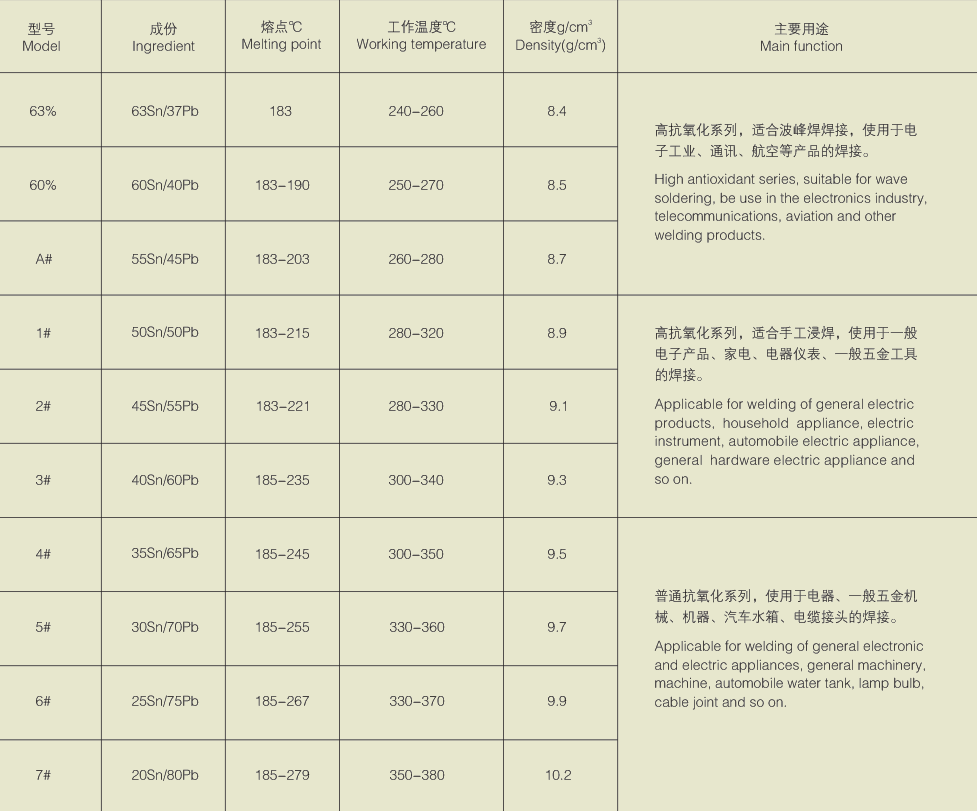

Notes: The temperature mentioned above is a working temperature of wave soldering under normal condition, the specific working temperature depends on the actual production process requirements.